Oil canning is a visual phenomenon that can occur in metal roofing, causing panels to appear wavy or distorted. While it's a natural characteristic of cold-rolled flat metal panels, it can be concerning for some building owners. Let's explore the facts about oil canning and how to address it.

What is Oil Canning?

- A visual effect where metal panels appear wavy or distorted

- Occurs in various metal roofing materials, including steel, copper, zinc, and aluminum

- Most common in standing seam roof systems

- Purely aesthetic - does not affect roof quality or structural integrity

Factors Influencing Oil Canning Visibility

- Roof color and finish

- Roof pitch

- Temperature and sunlight exposure

- Viewing angle and season

Common Causes of Oil Canning

- Inconsistencies in roof substructure

- Improper panel installation (e.g., twisting during placement)

- Over-tightened fasteners

- Structural movement

- Uneven stress at fastening points

- Temperature variations across the roof surface

- Wide panel widths

- Manufacturing issues (e.g., poorly adjusted roll formers)

Minimizing Oil Canning During Product Selection

- Choose reputable manufacturers with well-maintained equipment

- Consider narrower panel widths (12-16 inches instead of 24 inches)

- Opt for heavier gauge materials when appropriate

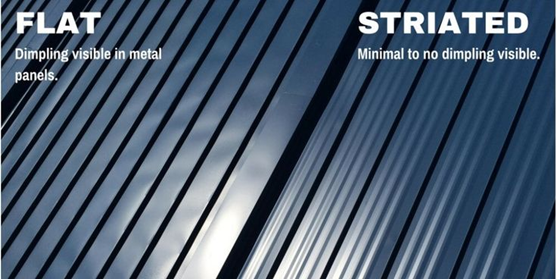

- Select panels with subtle configurations (striations, minor ribs, or planks)

Installation Best Practices to Reduce Oil Canning

- Handle panels correctly during transport and installation

- Ensure a level, plumb, and smooth roof deck

- Plan panel layout carefully to minimize stress

- Consider using a backer rod under panels for slight "bowing"

- Monitor for oil canning throughout installation and address issues promptly

Key Takeaways

- Oil canning is an aesthetic issue, not a structural or performance problem

- Proper material selection and installation techniques can minimize its occurrence

- Consult with manufacturers for project-specific strategies to reduce oil canning